Courtesy of S. Ghosh & Associates

Architects: S. Ghosh & Associates

Location: Lucknow, India

Team: Sudipto Ghosh and Sumit Ghosh (Principle Designers) as well as Mitesh Kapadia, Rashmi Vakharia, Naeem Rushnaiwala and Ketan Bhartia (Associate Designers)

Terminal Area: 20,000 sqm.

Site Area: 56,000 sqm.

Total Cost: Approx. US $ 23 million

Photographs: S. Ghosh & Associates

Courtesy of S. Ghosh & Associates

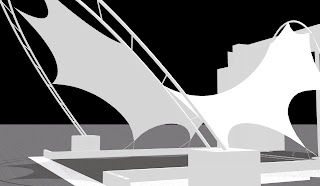

Unlike most buildings that bear the influence of the place where they take root, the Airport terminal of Lucknow, seems like it has an additional obligation to the sky. The intention of the architect was conceived with the primal image of plane in mind, the design explores the aesthetics of flight through the large wing like cantilevers spanning 26 meters.

The folds of the roof bring in glare free natural light to large double height areas of the terminal.The airports belong as much to the ether that keeps the air-crafts buoyant, as to the cities to which they become gateways. The notion of flight and man’s mythic fascination with it is reborn in every child as he folds his paper plane to launch it into the sky. The paper plane with its supple, folded wings – the symbol for that elemental flight that catches our fancy as children – becomes the starting point for the design of Lucknow Airport.

Courtesy of S. Ghosh & Associates

The terminal building’s elevation to the sky resembles the folded wings of the paper plane. Large wing-like cantilevers on either side of the 200m long terminal building suggest lightness and swiftness. The building itself appears as a dynamic object preparing to take flight. Inside, the gently curving ceiling gives the feeling of being under the belly of a giant aircraft.

Courtesy of S. Ghosh & Associates

The design of the building does not labor to represent the culture and heritage of the city, instead gets imprinted with the architects’ own experiences: nightmares about an aircraft crashing down through the roof, the exhilaration of flight, lightness, the indented front of the city as it wraps around the Gomti river, the ruins of the British Residency after the 1857 mutiny-ancient and unhomely, etc. Frosted etchings on the glass façade of the building bear the intricate patterns of chikankari work, Lucknow’s famous embroidery work.

Ground Floor – Courtesy of S. Ghosh & Associates

The terminal is designed as a one and a half floor integrated terminal with clear movement paths for international and domestic travelers. There are two security holds on the ground floor for connectivity by bus and two on the first floor for approach to the aircraft through passenger boarding bridges. Three passenger claim belts of 60m lengths have been provided for the arriving passengers. Modern facilities of international standards are important for the country’s new terminals. These not only bring revenue to the airport but also make flying a much more pleasurable experience.

The terminal building is friendly towards the physically challenged, there are no mobility thresholds and all floors are accessible by lift.

The structure is formed by a set of variable span portals with fixed connections spanned across by variable space trusses that form the final form of the ‘wings’. The design of the section of the portal has been arrived at using a composite of rolled sections forming an overall dimension of 733mm by 375mm. The maximum span of the portals is roughly 43m. The maximum cantilever achieved by the space trusses is 24m.

Structural Consultants: Descon United Pvt. Ltd.

MEP Consultants: Spectral Services Consultants

Landscape Architects: Design Accord

Lighting Consultants: Lighting Design Works

Acoustic Consultants: Suri & Suri

Glazing Consultants: Dema Consulting

Project Description provided by S. Ghosh & Associates.

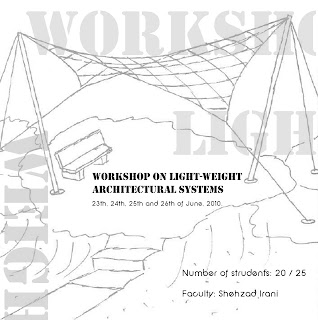

The IoA SPRING CHALLENGE event was an international design workshop intended for architecture students to explore integrated digital design and fabrication tools.

The IoA SPRING CHALLENGE event was an international design workshop intended for architecture students to explore integrated digital design and fabrication tools. The Challenge Program was organized as a six day event with 22 international students and 6 tutors. Introduction to Rhino/Grasshopper/Karamba was followed by project design development and daily reviews of student group projects which entered into a competition mode. The selected project was fabricated and assembled as a group effort. The event closed with an exhibition and presentation with guests. The output was a parametrically designed and digitally produced human scale structure fabricated out of corrugated cardboard.

The Challenge Program was organized as a six day event with 22 international students and 6 tutors. Introduction to Rhino/Grasshopper/Karamba was followed by project design development and daily reviews of student group projects which entered into a competition mode. The selected project was fabricated and assembled as a group effort. The event closed with an exhibition and presentation with guests. The output was a parametrically designed and digitally produced human scale structure fabricated out of corrugated cardboard. First, it has a silly name, the “Eureka Skyway”. Lets just call it the M20 Ashford Footbridge. It links two retail parks either side of the motorway, and also acts as a gateway to Ashford itself, an indication to motorway users that perhaps something of significance can be found here.

First, it has a silly name, the “Eureka Skyway”. Lets just call it the M20 Ashford Footbridge. It links two retail parks either side of the motorway, and also acts as a gateway to Ashford itself, an indication to motorway users that perhaps something of significance can be found here.

The £8m bridge was designed by Nicol Russell Studios with Jacobs, and built by BAM Nuttall. It was installed in May 2011 and opened in September 2011. There were rumours before it opened that it suffered from “wobble”… Three immediate precedents come to mind when viewing the Ashford bridge: Lancaster’s Lune Millennium Bridge (2001), and Newport’s City Footbridge (2006) are two. Closer to Ashford, Maidstone’s Lockmeadow Footbridge (1999) has a similar form. All four bridges share a resemblance to a giant crane, with twin masts tied together with cables, and a deck supported from cable stays. There are some structural advantages to this arrangement, chiefly that the angle of the cables supporting the deck is steeper, and hence they provide a stiffer and more efficient support. A significant disadvantage is that maintenance is more difficult, as cables are required with no low-level termination, making it more difficult to adjust or replace them in the future.

Three immediate precedents come to mind when viewing the Ashford bridge: Lancaster’s Lune Millennium Bridge (2001), and Newport’s City Footbridge (2006) are two. Closer to Ashford, Maidstone’s Lockmeadow Footbridge (1999) has a similar form. All four bridges share a resemblance to a giant crane, with twin masts tied together with cables, and a deck supported from cable stays. There are some structural advantages to this arrangement, chiefly that the angle of the cables supporting the deck is steeper, and hence they provide a stiffer and more efficient support. A significant disadvantage is that maintenance is more difficult, as cables are required with no low-level termination, making it more difficult to adjust or replace them in the future.

When the preliminary visuals for this bridge came out some time ago on the architect’s website, I thought it looked quite nice, appealing in its height and slenderness. In real life, the sheer scale of the bridge is much more difficult to accept. The bridge deck is roughly 100m long, with a 67m clear span. The masts are 38m high. It’s nowhere near as big as the Newport bridge (70m tall, 145m main span), but it’s still a very large structure to span a motorway. The span length is driven by the presence of two motorway slip roads, and a watercourse, forcing the bridge to be much larger than is normally required on motorways.

The bridge looks attractive enough when viewed from the motorway, but as a pedestrian it is quite overpowering. The masts tower far above you, and their angle of inclination makes them loom in a way that I don’t recall experiencing with vertical masts. What seems like a simple enough cable system when viewed in elevation becomes not only complex but positively confusing from most other perspectives. This is true of the forestays, but doubly so for the backstays. As well as tying the masts back to anchorage foundations, these also support a secondary deck, which curves below the main deck and provides part of a shallow gradient ramp access to the bridge’s north end. The end result is a web of cables with little apparent visual order.

What seems like a simple enough cable system when viewed in elevation becomes not only complex but positively confusing from most other perspectives. This is true of the forestays, but doubly so for the backstays. As well as tying the masts back to anchorage foundations, these also support a secondary deck, which curves below the main deck and provides part of a shallow gradient ramp access to the bridge’s north end. The end result is a web of cables with little apparent visual order..jpg) In the main span, the confusion is partly caused by the presence of a set of tie-down cables, two on each side of the deck, which anchor the foremast to the foundations. These are an odd presence on an asymmetric cable-stayed bridge, where normally the anchor cables are only required at the “rear end” of the bridge. Here, I guess the main deck is insufficiently heavy to hold the main masts in place on its own, or they are needed because the masts are offset to the side of the deck, or they minimise movement and vibration in the masts. Compare the Swansea Sail Bridge as an example of a cable-stayed bridge with an offset mast which doesn’t need to be tied down in this way (and where the mast has been more artfully shaped).

In the main span, the confusion is partly caused by the presence of a set of tie-down cables, two on each side of the deck, which anchor the foremast to the foundations. These are an odd presence on an asymmetric cable-stayed bridge, where normally the anchor cables are only required at the “rear end” of the bridge. Here, I guess the main deck is insufficiently heavy to hold the main masts in place on its own, or they are needed because the masts are offset to the side of the deck, or they minimise movement and vibration in the masts. Compare the Swansea Sail Bridge as an example of a cable-stayed bridge with an offset mast which doesn’t need to be tied down in this way (and where the mast has been more artfully shaped). Below deck, the oddest feature is a Y-shaped strut which holds the deck in place, presumably to restrain either vertical or lateral movement, or both. It has a sort of “tacked-on” feeling. My initial thought was that a corbel from the masts would have been better, but it’s not clear which mast you would add the corbel too, and what the effect on structural behaviour would have been. The view from below also highlights the somewhat rudimentary details where the cables are anchored to the deck.

Below deck, the oddest feature is a Y-shaped strut which holds the deck in place, presumably to restrain either vertical or lateral movement, or both. It has a sort of “tacked-on” feeling. My initial thought was that a corbel from the masts would have been better, but it’s not clear which mast you would add the corbel too, and what the effect on structural behaviour would have been. The view from below also highlights the somewhat rudimentary details where the cables are anchored to the deck.

The approach ramps at each end of the bridge are also very heavy, largely because of their height above the surrounding ground. There’s a stone-walled ramp at the south end, and an earth mound at the north end, into which stairs and a spiral ramp are cut. Growth of landscaping over time will help soften these, but they weigh the bridge down rather than allowing its slenderness to float free. Overall, it’s a bridge which had the potential to be great, but which is let down by the awkward resolution of many of the details. Notwithstanding the funder’s desire for a gateway structure, I found the sheer scale to be oppressive. The bridge at Swanscombe spanned the motorway with delicacy and modesty – the one at Ashford has neither.

Overall, it’s a bridge which had the potential to be great, but which is let down by the awkward resolution of many of the details. Notwithstanding the funder’s desire for a gateway structure, I found the sheer scale to be oppressive. The bridge at Swanscombe spanned the motorway with delicacy and modesty – the one at Ashford has neither.

A parametric experimentation at the university of Madrid on how constructing a Basic gear assembly, and then operating the same through a chipset connected to grasshopper and firefly.

Its an interesting innovation and I believe its going to get someplace. What’s incredible is that its built over a free platform!!!

Well this one took me sometime to compile, but its here nevertheless…

Complete ranking, links and their fans:

The Gropius Collection, owned by the Klassik Stiftung Weimar, is the world’s oldest collection of original Bauhaus works. The collection was significantly expanded with the acquisition of the Ludewig Collection in 2010, which contained 1,500 objects of functional design dating from 1780 to the present, including important Bauhaus works. Aside from the Bauhaus Archive in Berlin, the Bauhaus collection in Weimar is unarguably one of the world’s most important in terms of size and quality.

On 16. March 2012 the international jury awarded two second-place and two third-place prizes and conferred three honourable mentions.

The design proposal for the New Bauhaus Museum by Pedro Monteiro, Rodrigo Cruz, and Sérgio Silva establishes a volumetric relation with the Gauforum in regard to its location. The first thing you see is a tower of light. It leads the way. As you walk along the narrow line of Oskar Schlemmer’s logo, you are entering Bauhaus. As it gains depth, the two-dimensional design of the logo becomes a geometrical stone sculpture. Its occupation defines its architecture.

A first building, made of glass and steel, marks the beginning of the access route to the museum while a stone pathway leads to the museum entrance and the ground floor. This is where the social areas – foyer and café – are located The exhibition areas and the cinema are located in the underground floor, as well as a viewable depot for items from the Weimar Bauhaus collection. The depot’s location allows it to be a part of the exhibition, as well as to be used independently.

The exhibition areas are organized around a courtyard that may be used as an outside exhibition area, or as a venue for other events (Bauhaus Theatre, larger conferences, etc.). The floors above include the spaces where the access is more exclusive: the pedagogical areas on the first floor and the offices on the second floor.

The location of the exhibition areas under the ground is a consequence of the necessity to control their environment as much as possible. Since the terrain remains stable, those areas benefit from geothermal mass to reduce the need for insulation and mechanical control of the temperature. The courtyard organization, as a cloister, guarantees the natural circulation of air in those areas. The ventilated facade in stone assures that the rest of the building, where the environment conditions are not as demanding, is properly insulated and ventilated, reducing energy other expenditures.

The announcement of the winners officially concluded the architectural design competition. The two second-place prizes went to Johann Bierkandt (Landau) and the Architekten HKR (Klaus Krauss and Rolf Kursawe, Cologne).

The two third-place prizes went to Prof. Heike Hanada with Prof. Benedict Tonon (Berlin) and Bube/Daniela Bergmann (Rotterdam).

Three honourable mentions were awarded to the proposals by Karl Hufnagel Architekten (Berlin), hks Hestermann Rommel Architekten und Gesamtplaner GmbH (Erfurt), and menomenopiu architectures/Alessandro Balducci (Rome). The Klassik Stiftung Weimar will now begin negotiating with the four prize winners according to VOF procedure (Contracting Regulations for the Awarding of Professional Services). The jury provided the winners with recommendations for optimising their proposals in preparation for the VOF procedure.

The Klassik Stiftung Weimar will now begin negotiating with the four prize winners according to VOF procedure (Contracting Regulations for the Awarding of Professional Services). The jury provided the winners with recommendations for optimising their proposals in preparation for the VOF procedure.

All proposals of the second round of the competition are displayed at the Neues Museum in Weimar.

|

| This one’s by Shigeru Ban |

Design Concept

In case you missed the plans of the bubble, it will be an inflatable membrane, squeezing into the museum courtyard and transforming it into an auditorium, cafe, and meeting place. Plans are to erect the bubble for one month in the spring and fall.

In case you missed the plans of the bubble, it will be an inflatable membrane, squeezing into the museum courtyard and transforming it into an auditorium, cafe, and meeting place. Plans are to erect the bubble for one month in the spring and fall.The magazine also displays some new renderings of the bubble, showing more details of the structure (if you can call it that).

Liz Diller, founding principle of Diller, Scofidio + Renfro, shared the story of creating the pneumatic addition to the Hirshhorn Museum in Washington, DC. Commonly known as the “Bubble”, the inflatable event space is planned for the cylindrical courtyard of the National Mall’s modernist museum that was originally designed by Gordon Bunshaft in 1974. The first inflation of the “Bubble” is expected to take place at the end of 2013.

Below is a TED talk by Diller about the balloon, height, perceptions etc etc.. would be fun to see how they stabilize the balloon in winds…

The thin translucent membrane will fill the center of the Gordon Bunshaft building. Its sky blue tone will be darkest at the top and it will become more and more transparent toward the bottom floors so visitors can enjoy the sensation of looking up and practically being outside. Cable rigs compressing various areas of the bubble as it climbs up and over the museum ceiling give it a unique doughy look in stark contrast to the hard angular building.

The main floor of the Hirshhorn’s Bunshaft building includes 14,000 square feet of outdoor and courtyard space. The bubble will be erected during chillier seasons, allowing visitors to enjoy the open spaces year round with fun cushy seats scattered throughout, mimicking the softness of the walls. A giant water tube around the bottom of the bubble weighs the massive inflatable structure down and also acts as a bouncy bench.

The temporary inflatable space will also feature a make-shift auditorium that will seat up to 1,000 people for art films, events, lectures, and even site-specific installations. The Hirshhorn Bubble project has been in the works for almost two years and is expected to take form in the winter of 2012.

|

| Fig. 1.1 A superimposition of the previous pavilions. |

As announced back in February, Swiss architects Herzog & de Meuron and their Chinese collaborator Ai Weiwei will be designing this year’s Serpentine Gallery Pavilion at Hyde Park in London, a special edition that will be part of the London 2012 Festival, the culmination of the Cultural Olympiad. This will be the trio’s first collaborative built structure in the UK. If you do not know who weiwei is – you definitely know the “bird’s nest” which was designed for the last Olympics… They are the same guys…

As announced back in February, Swiss architects Herzog & de Meuron and their Chinese collaborator Ai Weiwei will be designing this year’s Serpentine Gallery Pavilion at Hyde Park in London, a special edition that will be part of the London 2012 Festival, the culmination of the Cultural Olympiad. This will be the trio’s first collaborative built structure in the UK. If you do not know who weiwei is – you definitely know the “bird’s nest” which was designed for the last Olympics… They are the same guys…Julia Peyton-Jones, Director, and Hans Ulrich Obrist, Co-Director, Serpentine Gallery, said: “It is a great honour to be working with Herzog & de Meuron and Ai Weiwei, the design team behind Beijing’s superb Bird’s Nest Stadium. In this exciting year for London we are proud to be creating a connection between the Beijing 2008 and the London 2012 Games. We are enormously grateful for the help of everyone involved, especially Usha and Lakshmi N. Mittal, whose incredible support has made this project possible.”

The Serpentine Gallery Pavilion will operate as a public space and as a venue for Park Nights, the Gallery’s high-profile programme of public talks and events. Connecting to the archaeological focus of the Pavilion design, Park Nights will culminate in October with the Serpentine Gallery Memory Marathon, the latest edition of the annual Serpentine Marathon series conceived by Hans Ulrich Obrist, now in its seventh year. The Marathon series began in 2006 with the 24-hour Serpentine Gallery Interview Marathon; followed by the Experiment Marathon in 2007; the Manifesto Marathon in 2008; the Poetry Marathon in 2009, the Map Marathon in 2010 and the Garden Marathon in 2011.

The 2012 Pavilion has been purchased by Usha and Lakshmi N. Mittal and will enter their private collection after it closes to the public in October 2012.

The Serpentine Gallery Pavilion 2012 designed by Herzog & de Meuron and Ai Weiwei will take place from 1 June to 14 October 2012. Those lucky to be in the neighborhood – do visit – the rest – rely on low res internet downloaded images…

The Ancient Egyptians were probably the first civilization to use pieces of fabric for shade. They also found sails useful for harnessing the power of the wind to travel in sailing boats from 3,500 BC.

Equipped with a Master’s in Membrane Structure, from Germany, Bhavini Mistry Jotani, M Archineer, engineers all design projects under the uniquely named Ahmedabad based Freitagmann, which specializes in designing, engineering and execution of light-weight structures and Innovative structures. Her views on the history of tensile forms is equally unique, “When I think of tensile, the Bedouin tents and the old Indian/arab markets with fabric roofs comes into my mind. But that is very personal and contextual,” and adds “In today’s times when one says tensile architecture, there is a whole new architectural language that springs up. Right from the big stadia and airport roof canopies to large span public spaces and mall-atriums.”

|

| McCoy DDA Games Village New Delhi CWG2010 |

Today, tensile architecture repre- sents, ease of use, light, elegant, versatile and sturdy fabric, that builders and architects endorse.

What comes to your mind, instantly, when you hear or read the word ‘Tensile Architecture’? We asked some profes- sionals using tensile fabrics with excellent, long-term results.

Richard Mcdonald, President, Taiyo Membrane, India Operations —

“Simplicity in geometric form but complex in design”!

Shehzad Irani, M Archineer, SCHAFBOCK– “Free flowing forms, fabric, lightweight structures, open spaces, warm natural light.”

Simran Dodeja, Senior Marketing Manager, McCoy Architectural Systems “Light weight structures, versatile, dynamic, free flowing forms, archite- cture in motion.”

While all agree that atrium structures, large canopies at airports, amphi- theatres, stadia, car parks, bus drop-offs, garden structures, cafeteria, food courts and gazebos, mall coverings, would benefit tremendously from the high translucency and properties of the membrane structure. Faraz Aqil, Director, Mehler Texnologies, adds a note of caution, “For best and long-term results, fabric selection plays an important role and the end users must be briefed on maintenance and cleaning of these structures.”

The advantages to the builder, to the architect, and to the end users, of tensile architecture, in place of the erstwhile used methods and fabrics

Reveals Shehzad Irani, “Using a tensile membrane roofing structure, reduces the overall loads on an existing structure, if designed properly. It gives a very good light quality, thereby reducing the overall illumination expenses of a space; the membrane roof itself is very flexible and hence is able to deflect considerably and hence resists earthquake loads. It also has a very small cross-sectional area, and hence cools down very quickly. Therefore in temperate climates, it doesn’t trap the heat in its mass. It is quite eco-friendly since the fabric is easily recyclable and the rest of the structure is steel, which can also be re-used. The manufacture of any of the components does not entail any toxic methodologies. They are very quick to install and demolish, since they are mostly pre-fabricated structures. They have a very low mass and hence can be even designed to retract/collapse easily”.

Ravi Mehta, who has shared his views on the advantages of tensile, on many occasions, gives a comprehensive list, that is technically precise and convincing. “The major advantage of using Textile roofing solutions is that, it allows natural light of very good quality, creating a very natural ambience, as it eliminates the need for artificial lighting, during daytime. Other materials like Glass or Polycarbonate, which also allow natural light, have the disadvantage of intense heat-gain, which necessitates high air-conditioning loads. Compa- ratively, Textile Architecture has lower heat gain and especially with certain solutions like Low E-membranes and double membranes, the requirement of air-conditioning can be reduced substantially. Being translucent, and not transparent like Glass, membrane diffuses the light through its entire surface and therefore at night, the entire roof comes alive and becomes a landmark with the illumination inside the roof.

|

| Manipal Food Court Polyklad |

Fabric being flexible, allows the architect to create striking forms and signature structures, extremely difficult with other rigid materials. If required, fabric structures can be designed to be modular and dismantlable. Being light, and flexible, they can also be easily stored and transported. A wide range of colors are available in certain types of fabric with customized options.”

Bhavini Mistry Jodani gives a comparative analysis, “The best advantage to the builders, is the coverage area, versus the cost per square meter area, when one compares tensile structures with regular concrete structures, or even run of the mill roofing solutions. The aesthetics of the tensile membrane structure, is always an architect’s delight, the light quality and the form of tensile, is like poetry.

Tensiles completely change the space quality. The volume of space that one gets in doing a tensile roof helps in decreasing the room temperature, especially in a tropical climate like ours. On the technical side, the cross section of tensile fabric is less and also fabric color is mostly white. A great percentage of sunlight is reflected back, while the thickness of membrane is so less compared to the concrete structure that it cools down equally faster. The amount of radiation from the membrane is lesser than a concrete structure.”

Simran Dodeja gives it a new dimension, “Tensile membrane structures offer versatility of form, giving the designer the ability to think on ‘out of the box’ solutions, virtually impossible with other materials. The pre-fabricated nature of these structures reduces construction time, allowing other on-site jobs to be completed simultaneously. Membrane Structures offer both roof and cladding, in one structural element.”

Faraz Aqil says that, besides being light, tensile fabrics are easy to install and maintain. They can be used to cover large areas with clear spans, they can take any form, shape or size; natural light helps in providing better surroundings and better ambiance.

Richard Mac Donald, wraps it up real crisp, “Pleasing to the eye, aesthetics, spanning large distances with minimal steelwork.”

Construction materials used towards ‘Green building objectives’ and Reduced ‘Carbon footprint’

|

| Tensile Structures for reduced carbon footprint |

“Construction activities consume voraciously – energy, and other materials, which have very high impacts on our carbon footprint. If we could use lesser materials by using more of our brains, it would go a long way in helping the environment; eventually leaving more for future generations to build with, especially in this time and age, when we have a lot of cutting edge software and tools, that can enable us to use less and lesser material for our buildings. Materials such as ‘Technical textiles’ can help in changing this attitude of want on use of materials, and move towards judicious use,” explains Shehzad Irani.

The strongest boost for the construction and building materials industry, is the bar rising initiated by the national planning departments that focus on ‘green’ building. The green building materials market is growing exponentially, with the residential market being a major driver. In addition to the residential market, efforts are been taken to use construction products that are manufactured, from renewable resources. Added to this, is the use of tensile fabrics, that have distinctive advantages, in promoting the ‘Green Building’ concept, in India’s construction arena.

“Tensile membrane Architecture is eco-friendly and is 100% recyclable. Even structures that support the membrane use steel, that is 100% recyclable, making this form of architecture perfect to achieve Green Building Solutions. Membrane structures allow diffused light and also help reduce heat load and can be extensively used as an alternative, to glass skylights, making these structures truly energy efficient” adds, Simran of McCoy.

Faraz Aqil boasts of Mehler’s eco-friendly fabrics, “We are committed to using greener technology and almost all our products are 100% recyclable. Mehler eco-care & Vinyl 2010 contribute to preserve the environment.”

|

| Taiyo Membrane Expo 88 from the Brisbane River |

“Nowadays a lot of non-linear, FDM based software have come into market like Forten4000, EASY, NDN. New software technology is being developed,, based on dynamic relaxation method, called Rhino membrane,” shares Bhavini Mistry Jotani.

Shehzad Irani, elaborates on the software packages that drive tensile architecture, “You require a FEA (finite element analysis) package that can do linear and non-linear structural analysis, a Force Density method based form-finder, to find the form for the structure, a patterning software, that can handle complex flattening of geodesic curvatures. ixForten 4000, is a very comprehensive and cost-effective tool. In addition, you need a Nurbs-modeling software that can handle 3Ds and easily prepare fabrication drawings. Vector- works, Rhino 4, Autocad, Revit, are all versatile software aids.

|

|

| Mehler texnnologies In Orbit Mall | |

In India, it is more the mental block of builders, consumers, architects and designers, who are not exposed to the changing trends, and remain soaked in age-old materials that are cheap and culture – friendly, that instill apprehe- nsions in their minds, to accept and adopt new membranes like tensile; resulting in the limited use of tensile fabrics in construction, besides the cost of these light fabrics.

Laments Bhavini, “The biggest challenge faced right now, is the base price of the material, since the fabric is not manufactured in India. We end up paying 30-40% more price compared to the European market, where most of the fabrics are also manufactured. Chinese fabrics are available in the market, but the quality is not reliable. More awareness needs to be created for the use of right technology and the benefits of tensile structures. One of the biggest challenge, in India, is to remove the blocks from people’s minds, that fabric does not mean temporary. Because of the flexibility of the material and the age old use of fabric (eg. Shamianas, temporary extension of shops during monsoons and summer) in our country, people have this notion, that the life of the structure is not long. On the contrary, with the strength the material possesses and the quality of the fabric that is available, the life of the structure can be from 15 to 35 years which more or less can be considered a permanent structure.”

Stressing on the need of the hour, Simran of McCoy says, “The biggest challenge that Tensile Fabric faces in India, is to create awareness about membrane architecture, which still remains to be explored by many designers and builders in the Country.”

Shehzad feels the lack of compe- tency in handling geometric precisions, in tensile architecture, “Fabric structure costs much more because of the rich specifications that have to be offered with it. They are extremely complex to design and engineer, since the behavior of the structure, geometry as well as the material is non-linear. Their installation, production requires, trained and skilled personnel, which is scarce in India.”

Faraz Aqil too lays emphasis on quality, “This is a cost effective solution, and not rocket science, but it is important to execute projects efficiently and fabricators should not compromise on the basic technical aspects of execution, in order to save costs.”

Richard Mac Donald is completely aware of the situation and challenges, and hence, is brutally honest in his views, as to how the myths of the practising architects, can ruin the image of the membrane industry, “Getting architects and developers to accept the cost of using membrane. They believe a thin material is not necessarily durable and long lasting. Roofing companies, new to the industry, not understanding the complexities of tensile membrane structures and believing, it is easy to design and build and subsequently they produce a membrane structure, that is poorly designed, detailed and built; thus giving the membrane industry a bad name.”

|

| Gera Germany Stadium |

Developing a Technical Guideline to Permanent Tensile Architecture

The tensile structure business has grown considerably in the last 10 years, and is predicted to grow exponentially, in the coming years. Such structures are becoming bigger and more sophisticated, as contractors, engineers and architects develop more confidence in their designs and reinforce them with their execution. Although the field may have evolved and more clients are interested in using them, they are still considered to be special – a new technology. Tensile surface structures do not figure widely in the design vocabulary of architects, engineers, urban planners, building owners and national authorities, and till that happens, their application will continue to be restricted.

Market projections, for tensile fabrics, pre- and post-economic slowdown, may be difficult to express in figures, without an accurate and deep study, but conservative turnovers would be close to 50-75 crores, per year.

How do big names fare, in the wake of poor acceptance, by the industry, of this new age, light material?

Says Ravi Mehta of Sujan Impex, which represents FERRARI, in India, “Initially we faced a lot of skepticism from architects, who were not aware of this new concept. However, slowly, as the architects in India got more exposed to international trends, and with a lot of foreign architectural firms also taking up projects in India, the concept of textile architecture has gained wide acceptance. People are realizing that, tensile architecture can be permanent, with life spans over 25 years.”

|

| Hyderabad AIRPORT |

Bhavini Mistry Jotani is optimistic about the market status, but is equally apprehensive of the cost and other issues. “India is an upcoming market for tensile structure. While European market is more or less saturated, and most of the international players are exploring the new asian markets, especially India and South East Asia. The tensile market in India, is around 15-20 years old. However, it is only for the last five years that it has been accepted in the Indian market. Many new players are coming into the market these days, but like any new technology or product in the market, some do justice to it by giving good solutions and by producing quality–tensile structure, while there are contractors who have half-baked knowledge and are invading the market, resulting in a disastrous end product, disappointing the end-user; creating a negative impact on the technology. I would say out of all the contractors and design-engineers in the field of tensile in India, only around 10-15% are qualified or have sufficient design-engineering knowledge of the technology and its application. Pre-recession saw fewer players, but the demand too was less. Post-recession has witnessed steep rise in the competition levels, almost 10 times, forcing everyone to quote competitive rates, and paradoxically, the base costs of fabric, steel and that of fabrication, have increased.”

Taiyo Membranes, FERRARI, and Mehler Texnologies lead the TA march, towards the new-age architectural world in India. McCoy is the perfect partner in project execution.

Faraz Aqil shares product features of his company, “Our Valmex FR Range, is one of the best PVC Coated Tensile memb- ranes available across the world.”

Salient features of Valmex FR includes: Both sides PVDF lacquered, 100% UV retardant, light weight and high strength, very easy cleaning and maintenance, resistance to microbial and fungal attack, translucent, thus enhancing power savings, flame retardant, 100% recyclable, a good example of environmentally safe and sustainable architecture, 10-15 years warranty and available in various width and sizes.

|

| Munich Olympic Stadium |

Ravi Mehta of Sujan Impex, says “FERRARI has a wide range of textiles for various exterior and interior applications such as, Permanent Roofing applications, Stretched Ceilings & Partitions, Solar Protection, Lightweight structures like tents, awnings & canopies.”

“FERRARI fabrics are made to suit all kinds of climatic conditions and are used in the coldest areas of Russia and North Europe, to the hottest desert areas of the Middle East. Tropical countries like Singapore and Malaysia use these fabrics widely” he adds.

Richard Mac Donald talks briefly his company’s excellence and product applications, “Taiyo is the oldest tensile membrane company in the world. It has over 50 years of experience in PTFE, PVC, ETFE, MDPE mesh and our company’s strength lies in design, detailing and ensuring high quality finishes. Our light-weight membranes are extremely durable for the harsh Indian environment. The most prominent membrane we sell is PTFE or Teflon coated fiberglass, which is extremely durable with a design life of over 50 years. PVC/PVDF is with a design life of 25 years, for the highest quality PVC fabric available in the market.”

|

| Taiyo Port Elizebath Stadium |

Simran shares information on the market status of McCoy, “McCoy Architectural Systems Pvt. Ltd. is known for its ability to design and execute the most Complex of Tensile Membrane Structures in India, with some very prestigious projects under its belt, like the D.Y. Patil Stadium Navi Mumbai, RK Khanna Tennis Stadium CWG 2010, DDA Games Village Swimming Pool Structures CWG 2010, and many more. The Company is constantly innovating in the field of Tensile Architecture and spreading awareness of Membrane Architecture through various methods.”

Shehzad confesses “Well very frankly, every fabricator would consider himself the leader, but some of the indigenous companies are–Western Outdoors, Shadeflex, Taiyo (not Indian), Construction Catalysers, McCoy Archite- ctural Systems, Skyshade technologies, Grorich, Polyklad, and Geodesic techniques.”

Bhavini Mistry Jotani feels “Tensile is the most apt material for our kind of climatic conditions. It’s just a matter of some time, before Tensiles would become an integral part of the Indian construction Industry.”

The future of Tensile Architecture, in India, may be uncertain, but one thing that remains undisputed is that, “Tensile is light, bright, tactile and versatile.”

In the case of the wooden shell in Stuttgart, this manipulation is achieved via hydraulic drives: these drives are positioned at the support points of the shell and produce movements, which specifically compensate deformations and material strains caused by wind, snow and other loads.

Specific support point movements counteract changing loads (such as through snow or wind) thereby reducing deformation and material tension. Much less material is therefore required for the shell construction compared to conventional, passive construction methods. The load balance is achieved using a Rexroth control system, which has been specially developed for hydraulic drives. The control system is mainly responsible for the complex hydraulic regulation of the shell structure. In this way, the structure is able to react to changes in the load within milliseconds.

In order to actively compensate loads and vibrations, it is first necessary to record or predict these influencing factors precisely. A second step involves calculation and realisation of the required counter-movements in real time. Researchers at the University of Stuttgart have developed simulation models which allow an exact prediction of the behaviour of the structure for this purpose. These take into account material stress as well as vibration behaviour under the influence of static and dynamic loads. The simulation models serve as a basis for development of control concepts, which calculate the required counter-movements for compensation of load and vibration effects according to the recorded measurements. These movements are then implemented precisely by the hydraulic system.

ILEK is a pioneer in research in the field of adaptive systems in the building industry; a first, small-scale prototype was already constructed with the sponsor from Stuttgart some years ago. The core competence of ISYS includes the analysis and specific influence of dynamic systems. For this purpose, the institute develops regulatory structures that create coordinated movements of the supporting structure. Bosch Rexroth is one of the world’s leading specialists in the field of drive and control technologies.

The project is integrated as a functional model in the Research Unit ‘Hybrid Intelligent Construction Elements’ supported by the DGF (German Research Foundation). This Research Unit brings together experts in the fields of mechanical engineering, aerospace engineering, civil engineering and process engineering.

Project participants

The following comparison might help to illustrate the astounding dimension of these shopping centres: the second in the Top 10 list, the Golden Resources Mall, offers 557,419 m², which is about the size of 75 football pitches. But it’s not all rosy for all mega malls in Asia: the South China Mall, the world’s largest mall with a commercial area of 600,153 m², reports a high vacancy rate due to decreased customer frequency. It is known as a dead mall.

|

| Sculpture with ropes |

|

| Attention to little details |

|

| vertical forms too.. |

|

| The sculpture at the turn-about |

| Some other explorations |

|

| Poster for the workshop |

|

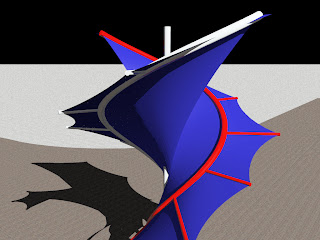

| Double cone structure |

|

| Bunching of fabric at the center. (it even has reinforcement sir!!!) |

|

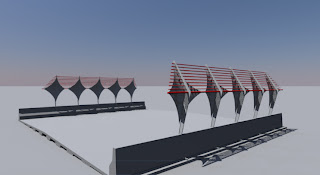

| Three continuous cones. |

|

| Eager students await opening of the fabric |

|

| The “SMILEY” plate |

|

| And the other plate…. |

|

| Students trying their hand at cut-outs. |

|

| Fixing details and laying out the cables in the fabric |

|

| Pretty maids – all in a row.. |

|

| Fixing cables and the corner details |

|

| With a lil’ help from my friends… |

|

| And.. we are almost there… |

|

| Trampoline? Testing..? Just having fun… |

|

| And some more fun… |

| Eye-lets on the edge |

| Fabrication errors |

| Fitting at the corner |

| How the designer thinks it should be… |

| Cargo Ratchets to tension the fabric |

| More Cargo ratchets |

| Facade with alternative panels |

| Flying mast with cables |

| Termination of the cable |

| The fabric over-shooting the system |

| Fixing details at the edge |

| Balloon-ing effect due to tensioning of the fabric |

| Corner cut-out radius |

| Tensioning of the point. |

| Facade panels (mock-up) |

For those who have been following this blog – and for those who haven’t been… firstly sorry, for the time since the last post. And doubly sorry, since in my anxiety to upload i deleted all my earlier post… Well it wouldn’t be my first experience at not backing up data and certainly not going to be my last experience at losing data… anyway, it is always new opportunity to start fresh – life gives us that each day…

Those who knew US, would know what i am talking of. It has been a glorious six years of working in Freitagmann from 2003 to 2010… But things have changed and have come to the level of bidding the heritage goodbye.

Among the happy memories there were of course Apollo hospital and the ganesh umbrella which reminds us of our naivete.. and our incredible capacity at working with our hands for long periods of time.

Then there was science city which we executed in 20 – 25 days, when we were just entering the world of computer aided tensile structures… and not really clear about all patterning and stuff…

There was IMS through which we made some great friends, and also along the way we have lost some dear ones…

There were immense number of times when we questioned where we stood and what we did and if we were moving in the right direction and if we were doing things that mattered… But principles drove us strong and long…

There were feeble attempts at discovery – and marvelous experiences at inventions.

All this and more that shall be a part of our memory. Thank you all those who have been in these… Miss you we shall.

Aideu.

|

| Apollo Green – Canopy |

|

| Figuring out the Ganesh canopy |

|

| Cutting patterns the old-fashioned way… |

|

| Thats the way to do the cnc plotting – completely not controlled |

| Ranpur. Creaseless and taut.. |

| Made some new friends… |

|

||||

| Design Experimentation |

|

| And some funky stuff… |

|

| some good rendering attempts (for that time) |

|

| and some explorations |

|

| And the struggle between the virtual and tactile… |

| Events where we didn’t sleep for nights in a row… |

|

| Some quick work… that fetched us results… |

|

| On the job and look out for problems.. |

| Somethings that didn’t quite fit.. |

|

| Sketch – before iPad and SketchUp and Samsung galaxy Tab |

|

| Even aesthetic inputs… the first Vibrant Gujarat at Science City.. |

|

| And thats what happens to fabrics that elongate… |