A stunning Catalan free-form vault has been designed and build by students during a one week workshop organised by Prof. Deplazes and Prof. Block from ETH Zurich. RhinoVAULT has been used for the design of the complex compression-only shape. For details, visit the homepage of the BLOCK Research Group.

Category: installation

Adaptive Construction: A timber tensile roof that adapts to loads

Institute for Lightweight Structures and Conceptual Design (ILEK) and Institute for System Dynamics (ISYS) of the University of Stuttgart in cooperation with Bosch Rexroth have realised an adaptive structure on a large scale for the first time. The shell made of wood is supported at four points. Three of these points can be moved individually by hydraulic cylinders and freely positioned in space. Sensors record the load status at numerous points on the structure. Targeted movements of the points of support counteract variable loads (for example through snow or wind) and thus reduce deformations and material stresses. Compared to conventional, passive structures this considerably reduces the use of materials for the shell. The load balancing takes place through a Rexroth control system which was especially developed for hydraulic drives. The core task of the control system is to implement the complex hydraulic control tasks of the shell structure. In this way the supporting structure can react to a change in the load status within milliseconds.

Institute for Lightweight Structures and Conceptual Design (ILEK) and Institute for System Dynamics (ISYS) of the University of Stuttgart in cooperation with Bosch Rexroth have realised an adaptive structure on a large scale for the first time. The shell made of wood is supported at four points. Three of these points can be moved individually by hydraulic cylinders and freely positioned in space. Sensors record the load status at numerous points on the structure. Targeted movements of the points of support counteract variable loads (for example through snow or wind) and thus reduce deformations and material stresses. Compared to conventional, passive structures this considerably reduces the use of materials for the shell. The load balancing takes place through a Rexroth control system which was especially developed for hydraulic drives. The core task of the control system is to implement the complex hydraulic control tasks of the shell structure. In this way the supporting structure can react to a change in the load status within milliseconds.An active vibration dampening and the adaptation to changing loads can be applied in many areas of construction, for example in stadium roofs, in high-rise buildings, in wide-spanning façade constructions or in bridges. The results of the research project at the University of Stuttgart thus enable a completely new construction method which not only saves resources but at the same time also considerably increases the performance of supporting structures. The active dampening of dynamic loads (for example from the effects of wind, earthquake or explosions) namely enables not only a drastic reduction in weight but furthermore also reduces material fatigue and damage to the structure. In order to be able to actively compensate loads and vibrations, these influencing factors initially have to be precisely recorded resp. predicted; a second step would be to calculate the necessary counter-movements in real time (and likewise promptly to implement them). Researchers from the University of Stuttgart developed simulation models for this purpose, enabling an exact prediction of the behaviour of the structure. The material stress as well as the vibration behaviour under static and dynamic exposure is thereby taken into account. These simulation models serve as a basis for the development of control concepts which calculate the necessary counter movements on load and vibration compensation depending on the recorded measured values. These movements are then precisely implemented through the hydraulics.

In order to be able to actively compensate loads and vibrations, these influencing factors initially have to be precisely recorded resp. predicted; a second step would be to calculate the necessary counter-movements in real time (and likewise promptly to implement them). Researchers from the University of Stuttgart developed simulation models for this purpose, enabling an exact prediction of the behaviour of the structure. The material stress as well as the vibration behaviour under static and dynamic exposure is thereby taken into account. These simulation models serve as a basis for the development of control concepts which calculate the necessary counter movements on load and vibration compensation depending on the recorded measured values. These movements are then precisely implemented through the hydraulics.

Read more about it Here and Here

Project participants:

Institute for Lightweight Structures and Conceptual Design (ILEK), University of Stuttgart

Prof. Werner Sobek, Stefan Neuhäuser, Christoph Witte, Dr. Walter Haase

Institute for System Dynamics (ISYS), University of Stuttgart

Prof. Oliver Sawodny, Martin Weickgenannt, Dr. Eckhard Arnold

Bosch Rexroth AG, Lohr a. Main

Dr. Johannes Grobe, André Fella

Contacts:

Stefan Neuhäuser: Tel.: 0711 685-63705,

Martin Weickgenannt: Tel.: 0711 685-66960,

André Fella: Tel.: 09352 18-1010,

‘Honey Scape’ Landscape Pavilion

Architects: Gonçalo Castro Henriques, X-REF Architectural Research & Development

Architects: Gonçalo Castro Henriques, X-REF Architectural Research & Development

Location: Ponte de Lima, Portugal

Client: Municipality of Ponte de Lima

Partners: X-REF, BÖ01 project management, Dagol Lda

Collaboration: Paulo Teodósio, Pedro Torres e Pedro Negrão (MergeLab), Helder Carvalho

Project Area: 280 sqm

Project Completion: 2012

Honey Scape is a dreamy temporary pavilion made of interlocking hexagonal sheets (or combs) of alveolar polycarbonate that create a dazzling display of light and shadow. “The combs act in part as the voussoirs of a parabolic arc supporting each other,” the designers explained. This allows them to “adopt a configuration of a double curvature surface… and adjust its size to their relative position in the structure.”

Honey Scape is a dreamy temporary pavilion made of interlocking hexagonal sheets (or combs) of alveolar polycarbonate that create a dazzling display of light and shadow. “The combs act in part as the voussoirs of a parabolic arc supporting each other,” the designers explained. This allows them to “adopt a configuration of a double curvature surface… and adjust its size to their relative position in the structure.” The components were digitally fabricated and constructed on site using metal connectors and a cable system. The resulting low-tech, 280 square meter pavilion commissioned by the municipality of Ponte de Lima and completed earlier this year heralds a new type of bio-tech art. Its main purpose, in addition to introducing a new aesthetic into the public realm, is to establish ultimate synergy between people and the built and natural environment.

The components were digitally fabricated and constructed on site using metal connectors and a cable system. The resulting low-tech, 280 square meter pavilion commissioned by the municipality of Ponte de Lima and completed earlier this year heralds a new type of bio-tech art. Its main purpose, in addition to introducing a new aesthetic into the public realm, is to establish ultimate synergy between people and the built and natural environment. Golden Honey Scape Pavilion Mimics a Giant Honeycomb in Portugal Inhabitat – Sustainable Design Innovation, Eco Architecture, Green Building A low-tech construction system was developed to build this complex structure. The system was complemented with metal connectors and a cable system on site. As it happens in the hives, this system required cooperative work to be assembled and became a reality. Networking and self-organization, which have inspired artificial intelligence, also inspired this solution. It offers bio-tech-art for a symbiosis between human and nature.

Golden Honey Scape Pavilion Mimics a Giant Honeycomb in Portugal Inhabitat – Sustainable Design Innovation, Eco Architecture, Green Building A low-tech construction system was developed to build this complex structure. The system was complemented with metal connectors and a cable system on site. As it happens in the hives, this system required cooperative work to be assembled and became a reality. Networking and self-organization, which have inspired artificial intelligence, also inspired this solution. It offers bio-tech-art for a symbiosis between human and nature. The installation avoids mimicking or confronting the landscape, rather seeking a man, nature and technology synergy. The structure recreates the honeycomb rules adapting to a lightweight double-curved surface in alveolar polycarbonate. The hexagonal geometry of the honeycomb is set according to three references – the parabolic arch, the double curved surfaces and the process of material adaptation. So the combs act in part as the voussoirs of a parabolic arc supporting each other, adopting a configuration of a double curvature surface (hyperbolic paraboloid), and adjusting its size to their relative position in the structure. The combs are larger at the base, decreasing in size and height towards the top of the structure. The generation and manufacture of the components relied on the use of scripting and digital fabrication.

The installation avoids mimicking or confronting the landscape, rather seeking a man, nature and technology synergy. The structure recreates the honeycomb rules adapting to a lightweight double-curved surface in alveolar polycarbonate. The hexagonal geometry of the honeycomb is set according to three references – the parabolic arch, the double curved surfaces and the process of material adaptation. So the combs act in part as the voussoirs of a parabolic arc supporting each other, adopting a configuration of a double curvature surface (hyperbolic paraboloid), and adjusting its size to their relative position in the structure. The combs are larger at the base, decreasing in size and height towards the top of the structure. The generation and manufacture of the components relied on the use of scripting and digital fabrication.Coca Cola Beatbox Pavillion

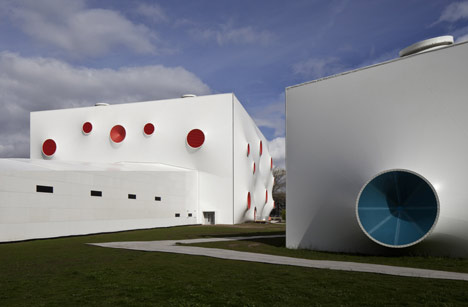

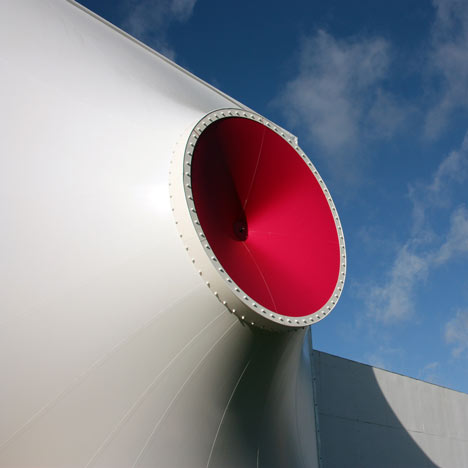

Olympic Shooting Range – Temporary

SPRING CHALLENGE 2012

The IoA SPRING CHALLENGE event was an international design workshop intended for architecture students to explore integrated digital design and fabrication tools.

The IoA SPRING CHALLENGE event was an international design workshop intended for architecture students to explore integrated digital design and fabrication tools. The Challenge Program was organized as a six day event with 22 international students and 6 tutors. Introduction to Rhino/Grasshopper/Karamba was followed by project design development and daily reviews of student group projects which entered into a competition mode. The selected project was fabricated and assembled as a group effort. The event closed with an exhibition and presentation with guests. The output was a parametrically designed and digitally produced human scale structure fabricated out of corrugated cardboard.

The Challenge Program was organized as a six day event with 22 international students and 6 tutors. Introduction to Rhino/Grasshopper/Karamba was followed by project design development and daily reviews of student group projects which entered into a competition mode. The selected project was fabricated and assembled as a group effort. The event closed with an exhibition and presentation with guests. The output was a parametrically designed and digitally produced human scale structure fabricated out of corrugated cardboard.A Giant ball of Gas in Washington DC.. hey what’s new??

In case you missed the plans of the bubble, it will be an inflatable membrane, squeezing into the museum courtyard and transforming it into an auditorium, cafe, and meeting place. Plans are to erect the bubble for one month in the spring and fall.

In case you missed the plans of the bubble, it will be an inflatable membrane, squeezing into the museum courtyard and transforming it into an auditorium, cafe, and meeting place. Plans are to erect the bubble for one month in the spring and fall.The magazine also displays some new renderings of the bubble, showing more details of the structure (if you can call it that).

Liz Diller, founding principle of Diller, Scofidio + Renfro, shared the story of creating the pneumatic addition to the Hirshhorn Museum in Washington, DC. Commonly known as the “Bubble”, the inflatable event space is planned for the cylindrical courtyard of the National Mall’s modernist museum that was originally designed by Gordon Bunshaft in 1974. The first inflation of the “Bubble” is expected to take place at the end of 2013.

Below is a TED talk by Diller about the balloon, height, perceptions etc etc.. would be fun to see how they stabilize the balloon in winds…

The thin translucent membrane will fill the center of the Gordon Bunshaft building. Its sky blue tone will be darkest at the top and it will become more and more transparent toward the bottom floors so visitors can enjoy the sensation of looking up and practically being outside. Cable rigs compressing various areas of the bubble as it climbs up and over the museum ceiling give it a unique doughy look in stark contrast to the hard angular building.

The main floor of the Hirshhorn’s Bunshaft building includes 14,000 square feet of outdoor and courtyard space. The bubble will be erected during chillier seasons, allowing visitors to enjoy the open spaces year round with fun cushy seats scattered throughout, mimicking the softness of the walls. A giant water tube around the bottom of the bubble weighs the massive inflatable structure down and also acts as a bouncy bench.

The temporary inflatable space will also feature a make-shift auditorium that will seat up to 1,000 people for art films, events, lectures, and even site-specific installations. The Hirshhorn Bubble project has been in the works for almost two years and is expected to take form in the winter of 2012.